FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

Before discussing this issue, let's first understand what ceramic circuit boards are and what FR4 circuit boards are.

Ceramic circuit board: It is a type of circuit board manufactured based on ceramic materials, also known as a printed circuit board (PCB). Unlike common glass fiber reinforced plastic (FR-4) substrates, ceramic circuit boards use ceramic substrates, which can provide higher temperature stability, better mechanical strength, better dielectric properties, and longer lifespan. Ceramic circuit boards are mainly used in high-temperature, high-frequency, and high-power circuits, such as LED lamps, power amplifiers, semiconductor lasers, RF transceivers, sensors, and microwave devices.

Circuit board: It is a basic material for electronic components, also known as a circuit board, PCB board (Printed Circuit Board), or printed circuit board. It is a carrier for assembling electronic components by printing metal circuit patterns on non-conductive substrates, and then producing conductive pathways through processes such as chemical corrosion, electrolytic copper, and drilling.

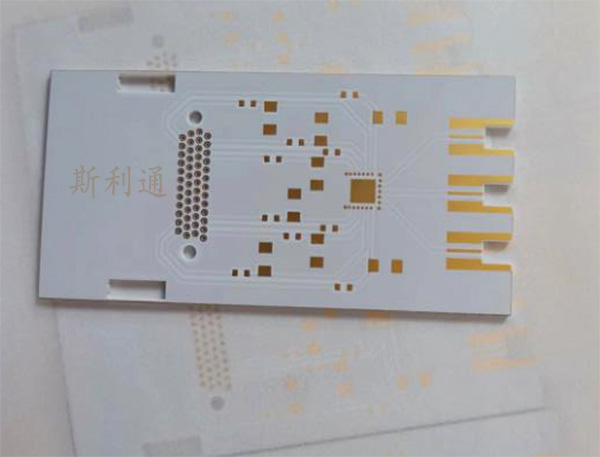

The following is a comparison between Sliton ceramic substrate and FR4 substrate, including their differences, advantages and disadvantages

陶瓷PCB

The application field is divided into materials:

Alumina ceramic (Al2O3): It has excellent insulation, high-temperature stability, hardness, and mechanical strength, and is suitable for high-power electronic equipment.

Aluminum nitride ceramic (AlN): With high thermal conductivity and good thermal stability, it is suitable for high-power electronic devices and LED lighting and other fields.

Zirconia ceramic (ZrO2): With high strength, high hardness, and wear resistance, it is suitable for high-voltage electrical equipment.

From process division:

HTCC (High Temperature Co fired Ceramics): Suitable for high-temperature and high-power applications, such as power electronics, aerospace, satellite communication, optical communication, medical equipment, automotive electronics, petrochemical and other industries. Product examples include high-power LEDs, power amplifiers, inductors, sensors, energy storage capacitors, etc.

LTCC (Low Temperature Co fired Ceramics): Suitable for the manufacturing of microwave devices such as RF, microwave, antennas, sensors, filters, power splitters, etc. In addition, it can also be used in medical, automotive, aerospace, communication, electronics and other fields. Product examples include microwave modules, antenna modules, pressure sensors, gas sensors, acceleration sensors, microwave filters, power splitters, etc.

DBC (Direct Copper Ceramic): Suitable for heat dissipation of high-power semiconductor devices (such as IGBT, MOSFET, GaN, SiC, etc.), with excellent thermal conductivity and mechanical strength. Product examples include power modules, power electronics, electric vehicle controllers, etc.

DPC (Direct Copper Multilayer Printed Circuit Board): Mainly used for heat dissipation of high-power LED lamps, it has the characteristics of high intensity, high thermal conductivity, and high electrical performance. Product examples include LED lights, UV LEDs, COB LEDs, etc.

LAM (Hybrid Ceramic Metal Laminate): can be used for heat dissipation and electrical performance optimization in high-power LED lights, power modules, electric vehicles, and other fields. Product examples include LED lights, power modules, electric vehicle motor drivers, etc.

IC carrier boards, soft hard bonding boards, and HDI blind buried hole boards are commonly used PCB types, which are applied in different industries and products, as follows:

IC carrier board: IC carrier board is a commonly used printed circuit board, mainly used for chip testing and production in electronic devices. Common application industries include semiconductor production, electronic manufacturing, aerospace, military, and other fields.

Soft hard combination board: Soft hard combination board is a composite material board that combines flexible circuit boards with rigid circuit boards, and has the advantages of both flexible and rigid circuit boards. Common application industries include consumer electronics, medical equipment, automotive electronics, aerospace, and other fields.

HDI blind buried hole board: HDI blind buried hole board is a high-density interconnect printed circuit board with higher line density and smaller aperture to achieve smaller packaging and higher performance. Common application industries include mobile communication, computers, consumer electronics, and other fields.

Follow us

customer service