FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

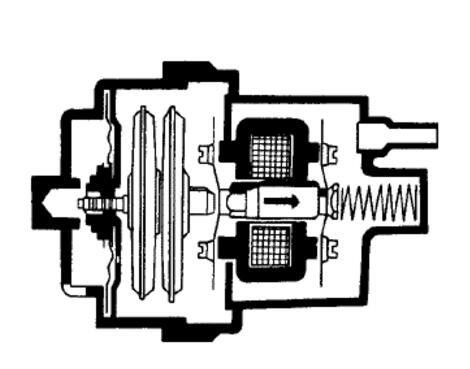

Intake manifold pressure sensor, abbreviated as MAP. It is connected to the intake manifold through a vacuum pipe, which senses the changes in vacuum inside the intake manifold according to different engine speeds and loads. Then, the change in resistance inside the sensor is converted into a voltage signal for the ECU to correct the fuel injection quantity and ignition timing angle.

In modern cars, the malfunction of the intake manifold pressure sensor is the most easily felt. Once it stops working, the engine's fuel injection volume and ignition timing will be disrupted, ranging from stalling to engine scrapping. The manufacturer will not be unaware of such serious consequences, so the quality of the intake manifold pressure sensor must be absolutely guaranteed, even if the engine breaks down, the sensor cannot be damaged.

Pressure sensors are a typical representative of MEMS technology, and another commonly used MEMS technology is the MEMS gyroscope. At present, several major MEMS system suppliers, such as BOSCH, DENSO, CONTA, and other companies, have their own designed specialized chips with similar structures. Advantages: High integration, small sensor size, and small sensor size with small connectors, making it easy to arrange and install. The pressure chip inside the sensor is completely encapsulated in silicone, which plays a role in corrosion resistance, vibration resistance, and greatly improves the sensor's service life. Mass production has low costs, high yield, and excellent performance.

Some manufacturers of intake pressure sensors use universal pressure chips, which integrate peripheral circuits such as pressure chips, EMC protection circuits, and pin pins of connectors through the substrate. The pressure chips are installed on the back of the substrate, and generally use a single-layer double-sided substrate.

The substrate is the core of the intake manifold pressure sensor, and everyone is aware of the working environment on the engine. High temperature, gasoline corrosion, oil corrosion, vibration, dust, and so on can all have a significant impact on the sensor substrate. Previously, sensors were generally sealed and protected with an outer shell, but their lifespan was not long. The outer shell cannot prevent vibration and the impact of ultra-high temperature, and ordinary substrates simply cannot withstand it.

So there is the application of ceramic substrates for intake manifold pressure sensors. Ceramic substrates are an emerging product that has only emerged in China in recent years. Combining the advantages of special ceramics, their application in the field of circuit boards can be said to complement each other. Especially when applied to intake manifold sensors, it can effectively improve sensor life and enhance sensor performance.

The advantages of ceramic substrates actually meet the needs of the intake manifold. Firstly, ceramic substrates have ultra-high mechanical strength and can withstand earthquakes effectively; Secondly, ceramic substrates can withstand high temperatures, with a maximum operating temperature of up to 2300 ℃; Then, because the ceramic substrate is an inorganic material, it can withstand various types of corrosion, strong acids and alkalis, and gasoline engine oil is not a big deal; Finally, the dielectric constant of the ceramic substrate is very excellent, allowing for better transmission and collection of data, which is crucial for precision engines.

Many people have bought low-end domestic cars and haven't been driving for long before they have various small problems. Of course, I'm not talking about black domestic cars here. Domestic cars have a long way to go to reach the world's peak, especially in the engine area. The domestic intake manifold pressure sensor even uses a simple FR-4 plate and is then sealed. Of course, it's okay to do this, but not all cars drive on flat highways for a lifetime. There's also a speed bump at the toll station. So it is unstoppable that sensors used in ceramic substrate applications have become mainstream. As for when domestic manufacturers can truly reduce profits to the lowest and produce true "Made in China", it will also be the time for the rise of ceramic substrates.

Follow us

customer service