FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

As is well known, semiconductor materials are greatly affected by environmental temperature during operation, especially in the high-temperature environment in which they work. With the booming development of the automotive market, LED headlights in cars are gradually replacing halogen bulbs and becoming the basic equipment of the new generation of cars. From daytime running lights to low beam headlights, and even high beam headlights, LED headlights are everywhere.

Assuming that the specifications of one of the models are approximately: input voltage 12/24V, power 35/45W, LM 2600-3600. To meet this specification, LED must also use high-power products. The photoelectric conversion efficiency of high-power LEDs is very low, with only 10% to 25% of electrical energy converted into light energy during operation, and almost all the rest converted into thermal energy. In addition, car headlights are generally installed in the hot engine compartment, and the heat generated by the high-temperature water tank, engine, and exhaust system places LED headlights in a harsh working environment. The light output of LED will affect its PN junction temperature stability due to its own heat or high temperature from the engine compartment, and the LED luminous flux Ф Important parameters such as V and wavelength are directly affected by the PN junction temperature, and this poor temperature cycle will lead to a sharp decrease in luminescence efficiency and lifespan. Therefore, heat dissipation has become an important issue in the design of LED as a light source for automotive headlights.

The high-power LED needs to be soldered onto the circuit board and tightly fixed on the heat sink for heat dissipation. The heat generated during LED operation is transmitted through a circuit board to an aluminum heat sink with good thermal conductivity. The fins of an aluminum radiator come into extensive contact with air to dissipate heat. The relevant heat conduction diagram is as follows.

In order to effectively reduce the thermal resistance between the heat sink and the circuit board, thermal conductive media is filled between them. However, the thermal conductivity of the circuit board itself often restricts the heat dissipation capacity of the entire system. The traditional LED installation circuit board is made of FR-4 material, also known as epoxy glass cloth laminate, with a thermal conductivity of approximately 0.25-0.4W/M.K. It is precisely because of its low thermal conductivity that the heat of high-power LEDs cannot be effectively transferred to the external heat sink. In response to this requirement, Sliton has developed an aluminum oxide ceramic substrate specifically designed for automotive headlights. The substrate uses aluminum oxide ceramic adhesive lines, with a thermal conductivity of 28-32W/m-K, which is 70-80 times that of ordinary FR-4 materials.

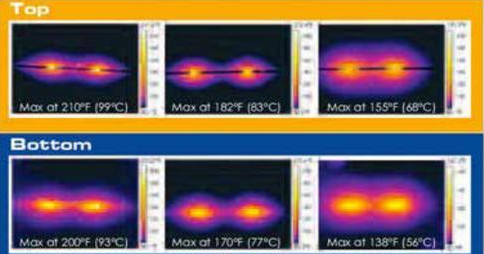

In order to more realistically demonstrate the good thermal conductivity of Sliton alumina ceramic substrate relative to FR-4 plate, we conducted relevant experiments.

The experimental conditions are: a dedicated chip heating resistor is welded on the 92ML and FR-4PCB boards, and a fixed constant current source is added at both ends of the resistor to generate heat. After one hour, the temperature is measured and recorded using an infrared thermometer.

As can be seen from the above figure, under the same external environment conditions, the temperature of the top surface and bottom surface of the 92ML series board can be reduced by about 30 ℃ and 37 ℃ respectively compared to the FR4 board.

In summary, it can be seen that the Sliton alumina ceramic substrate series can effectively reduce the node temperature of automotive headlights LED, thereby greatly increasing the service life and luminous efficiency of LED, and is particularly suitable for use in environments with high stability requirements, more harsh environmental temperatures, and sealing.

Follow us

customer service