FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

Before discussing this issue, let's first understand what 99% alumina ceramics are: 99.6% alumina ceramics is a kind of engineering ceramic materials with high purity, high hardness, high temperature resistance and high corrosion resistance, in which the alumina content is as high as 99.6% or more. It has good physical, chemical and mechanical properties, such as excellent insulation properties, high thermal conductivity, low dielectric constant, low dielectric loss, high bending strength, high wear resistance and corrosion resistance.

99.6% alumina ceramics have a wide range of applications, such as electronics, machinery, aerospace, chemical, medical, lighting and other fields.

In the field of electronics, 99.6% of alumina ceramics are often used to manufacture high-power, high-frequency and high-reliability electronic components and circuit boards;

In the mechanical sector, 99.6% of alumina ceramics are commonly used in the manufacture of high-performance components such as bearings, pneumatic and hydraulic components;

In the aerospace sector, 99.6% of alumina ceramics are commonly used in the manufacture of high-temperature structural materials, aircraft engine components and conductive ceramics.

In the chemical and medical fields, 99.6% of alumina ceramics are commonly used in the manufacture of chemical reactors, medical devices, etc.

In short, 99.6% alumina ceramics are considered to be an important advanced engineering material due to their excellent properties and wide range of application fields.

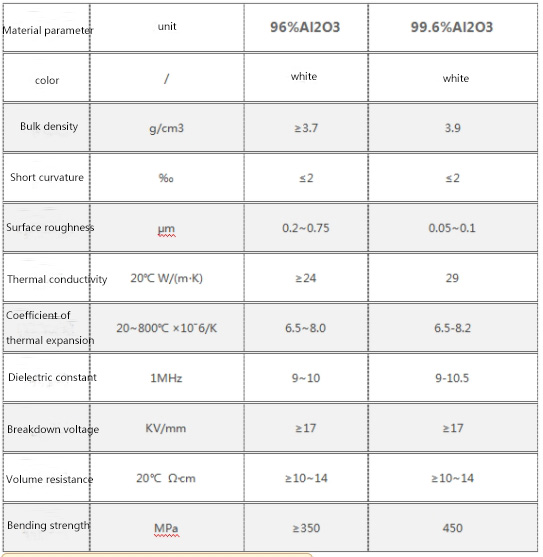

To compare the difference between 99 and 96 alumina ceramics, let's first compare the performance:

The above is a comparison of 99.6% alumina ceramics and 96% alumina ceramics in various aspects of performance, including hardness, thermal conductivity, bending strength, density, wear resistance, corrosion resistance, dielectric constant, thermal expansion coefficient and surface roughness. As can be seen from the table, 99.6% alumina ceramics are better than 96% alumina ceramics in most performance indicators, but the gap between the two is small in terms of wear resistance and corrosion resistance.

Where are 99.6% of alumina ceramic circuit boards and 96% of alumina ceramic circuit boards used?

99.6% of alumina ceramic circuit boards and 96% of alumina ceramic circuit boards are also different in the field of application. The following are their specific applications in the field of circuit board applications:

1. 99.6% of alumina ceramic circuit board applications:

(1) High-frequency circuit: because of its good conductivity, it can be applied to the manufacture of high-frequency circuits, such as microwave circuits, antennas, etc.

(2) High temperature circuit: because of its good high temperature resistance, it can be applied to the manufacture of high temperature circuits, such as IGBT, automotive electronics, aerospace electronics, etc.

2. 96% of alumina ceramic circuit board applications:

(1) Ordinary circuit: because of its low price, it is used in the manufacture of ordinary circuit boards.

(2) LED lights: because of its good thermal conductivity, it can be applied to the manufacture of heat dissipation components of LED lights. In summary, 99.6% of alumina ceramic circuit boards and 96% of alumina ceramic circuit boards are also different in the field of circuit board application. According to the needs of different application scenarios, different categories of alumina ceramic circuit boards can be selected.

Where is the difficulty of 99.6% alumina alumina ceramics compared to 96% alumina ceramics?

Compared with 96% alumina ceramics, 99.6% alumina ceramics have higher purity, higher hardness and better wear resistance, corrosion resistance, high temperature resistance and other properties. Therefore, the preparation of 99.6% alumina alumina ceramics relative to 96% alumina ceramics, the main difficulty in the following aspects: 1. Material selection: The preparation of high-purity alumina powder is difficult and the cost is high, and high-quality raw materials need to be selected, and the purity and particle size of raw materials are strictly controlled to ensure the purity and stability of the prepared ceramic materials.

2. Process control: The preparation of high-purity alumina ceramics requires strict process control, including powder preparation, mixing, molding, sintering and other links, each step of the process needs to be strictly controlled to ensure the quality and stability of the prepared ceramic materials.

3. Sintering process: The preparation of high-purity alumina ceramics needs to be sintered at high temperature, and the sintering temperature of 99.6% alumina materials is higher than that of 96% alumina ceramics, and the sintering process is more complex, prone to problems such as uneven sintering and excessive sintering shrinkage, and higher requirements for sintering process control.

4. Molding difficulty: Due to the high hardness of 99.6% alumina material, the molding difficulty is relatively greater, and more precise molding processes need to be used, such as plasma molding, injection molding, etc., to ensure molding accuracy and quality.

In summary, alumina ceramics of 99.6% alumina have higher requirements and difficulties than alumina ceramic substrates of 96% in material selection, process control, sintering process and molding difficulty, but it has better performance and application prospects, so it has important application value in some high-end application fields.

Follow us

customer service