FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

On November 2, The General Office of the State Council issued the "New Energy Automobile Industry Development Plan (2021-2035)" (hereinafter referred to as the "Plan") proposed that by 2025, the average power consumption of new electric passenger vehicles will be reduced to 12.0 KWH / 100 km, and the sales volume of new energy vehicles will reach about 20% of the total sales volume of new vehicles.

"The highlights of this plan can be summed up as' four new ': adapt to the new situation, adapt to new requirements, clarify the new direction, and put forward a new path." Xin Guobin, Vice Minister of Industry and Information Technology, said that a new round of global scientific and technological revolution and industrial change are booming, and the development of new energy vehicles has both new challenges and rare development opportunities, and it is necessary to seize opportunities to promote the development of new energy vehicle industry to a new level.

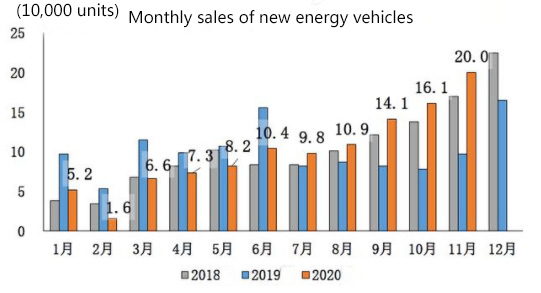

(Photo source: China Automobile Association)

New energy vehicles contain a large number of high-voltage, high-power devices, such as IGBT, MOSFET, etc., have high requirements for heat dissipation, so that the layout of PCB can not be too dense, which further increases the amount of PCB in new energy vehicles. For each new energy vehicle, the total PCB board required for the above equipment only reaches about 0.8 square meters. Compared with the 12V electrical system commonly used in traditional fuel vehicles, the power platform of new energy trams can support more intelligent equipment loads, but at the same time, the heat dissipation requirements are higher. This also means the need for a more advanced, more matched, more environmentally friendly PCB board - silicon nitride ceramic substrate

Why is the silicon nitride ceramic substrate the most suitable PCB board for new energy vehicles?

Silicon nitride has high strength and fracture toughness at high temperatures. Can adapt to high temperature and high pressure working environment. Silicon nitride has a high heat dissipation coefficient, a thermal expansion coefficient that matches the chip, and a very high heat shock resistance. It can dissipate the high heat in the power system in time, ensure the normal operation of each high-power load, and protect the normal work of the chip. Equipment using silicon nitride ceramic substrates can further reduce the size, save more space, and provide more possibilities for new energy vehicles. Silicon nitride also has very high chemical resistance and good wear resistance, which can extend the service life of electronic equipment in the harsh environment inside the car. Silitong silicon nitride ceramic substrate also provides high-end customized services, which can be mass produced according to the product design drawing and requirements given by the user, so that the user can have more choices and be more humane.

The shape and pattern of global automobiles are being reshaped, and the development of "electrification, intelligence, networking, and sharing" of automobiles in the 5G era has been the general trend. New energy vehicles need silicon nitride ceramic substrates, and silicon nitride substrates will surely glow and heat up with the wave of new energy vehicles for a long time in the future. Sliton will work with customers to face the challenges and opportunities of the future market.

Follow us

customer service