FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

FOLYSKY(WuHan) LTD.

According to the latest research report of the global market, the global 5G Internet of Things market is about to reach $700 million in 2020, and with the need for iot devices and the gradual popularization of 5G technology, the market data is expected to double to $6.3 billion by 2025.

With the development and popularization of 5G Internet of Things, 3D Sensing and sensing technology is about to usher in a round of rapid growth. As the core device of 3D Sensing and sensing system, VCSEL will undoubtedly have a major breakthrough in semiconductor laser technology.

Yole expects the VCSEL market to grow from $1.247 billion in 2019 to $3.775 billion in 2024, a compound annual growth rate of 31%. The market data undoubtedly proves that VCSEL is one of the fastest growing segments of the photonics market.

资料来源:Yole

1, VCSEL laser

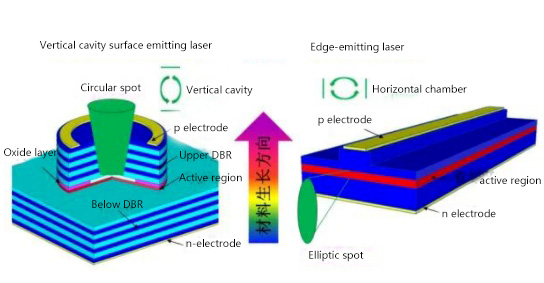

VCSEL is essentially a semiconductor laser, laser is used to emit laser device, and semiconductor laser is a semiconductor material as the working material to emit laser device, according to the structure of the laser chip, semiconductor laser can be divided into edge emitting laser (EEL) and vertical cavity surface emitting laser (VCSEL).

VCSEL has the following advantages over EEL:

(1) The circular spot is easier to achieve coupling with the fiber and the coupling efficiency will be much higher

(2) Vertical light output is easier to achieve two-dimensional plane and photoelectric integration

(3) Low threshold current

(4) High photoelectric conversion efficiency

(5) Long service life

(6) Strong modulation ability

(7) Can be integrated with large-scale integrated circuits

(8) Without cleavage, the test can be carried out on film after packaging

(9) Operate in a single longitudinal mode over a wide range of temperatures and currents

The VCSEL has also shown its excellent performance in sensor applications, with a simpler structure, smaller volume and more accurate distance than the LED light sources used in earlier 3D camera systems.

Ii.VCSEL application trend

Due to the gradual growth of the infrared component application market, it has led to the vigorous development of terminal mobile phone 3D sensing technology, vehicle optical transceiver and optical fiber transmission

1. Mobile phone market support

TOF is one of the three mainstream 3D Sensing technology routes at present, the other two are binocular stereoscopic imaging and structured light. Currently, structured light and TOF are relatively mature solutions. TOF quickly became widely recognized in the mobile terminal due to its advantages of simple structure, smaller module size, longer detection distance and lower material cost.

The working principle of TOF is that the VCSEL laser source is used as the transmitting end to emit continuous infrared light to the target, and then the infrared CIS is used as the receiving end to receive the light signal returned by the object.

Apple has configured a "TOF optical sensor" on the rear main camera module of the iPhone 7, and the iPhone X not only continues the above application, but also uses 3D structured light and TOF optical sensor components on the front face recognition module, pushing the VCSEL TOF directly to a peak.

VCSEL manufacturers are generally optimistic about the application prospects of ToF technology in smart phones. But in fact, 5G will bring much more to the VCSEL industry.

2. The rise of the automobile market

Under the surging tide of global autonomous driving, and stimulated by the rapid growth of "new infrastructure" applications proposed by the Standing Committee of the Political Bureau of the CPC Central Committee, the demand for automotive lidar industry will undoubtedly add a new high.

Compared with the current expensive mechanical lidar, VCSEL's solid-state liDAR can better achieve the performance required by the vehicle. VCSEL's solid-state liDAR has higher reliability, stability and miniaturization, laying the foundation for large-scale application of lidar in the automotive field.

Since its birth, VCSEL has been the core device of a new generation of optical storage and optical communication applications, and has been applied in optical parallel processing, optical recognition, optical interconnection system, optical storage and other fields. With the improvement of process and material technology, VCSEL devices have begun to show their advantages in power consumption, manufacturing cost, integration, heat dissipation and other fields, and are gradually applied to commercial applications such as industrial heating, environmental monitoring, medical equipment and consumer applications such as 3D perception.

Three, VCSEL packaging

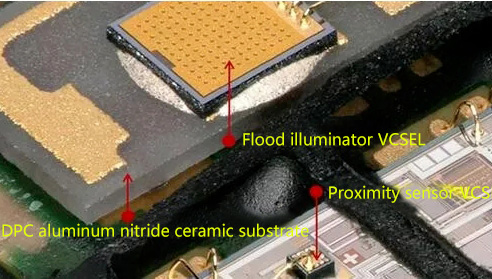

VCSEL chip conversion efficiency is low, leading to its serious heat dissipation problems, want to solve this problem, we need to start from the fundamental - chip material, and the traditional circuit board FR-4 and FE-3 is obviously unable to meet this requirement, ceramic plate has been with its heat dissipation performance as the main advantage, Naturally, it can solve the problem of heat dissipation difference of VCSEL well.

The power density of VCSEL is very high, and the ceramic circuit board has a high thermal expansion coefficient matching with VCSEL, so as to solve the stress problem caused by the mismatch of thermal expansion between chip and substrate. The DPC ceramic circuit board makes the metal edge closely combined with the ceramic substrate, avoiding the additional paste process, coordination accuracy and other problems in the later assembly process, as well as the reliability problems caused by the aging of the glue.

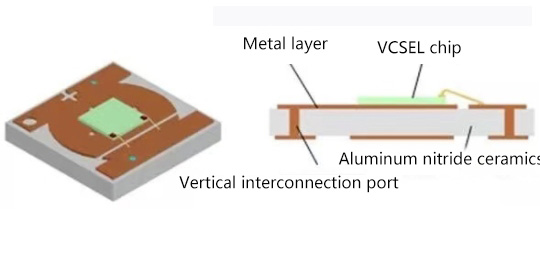

VCSEL structure is vertical structure, DPC ceramic circuit board has a unique high resolution, high flatness and high reliability of vertical interconnection and other technical advantages more suitable for its vertical eutectic welding, eliminating LTCC, HTCC and other thick film substrate size accuracy is not high, line rough and other defects.

VCSEL requires the lens to be set up above the chip, that is, the substrate needs to be made into a three-dimensional chamber, and our company's ceramic circuit board can not only make a planar circuit board, but also can make a three-dimensional circuit board - dam products, its material is inorganic ceramic material, thermal expansion coefficient matching, there will be no delamination, warping and other phenomena in the preparation process.

The ceramic circuit board of DPC film technology almost meets the packaging requirements of VCSEL. DPC ceramic circuit board, also known as direct coppered ceramic circuit board, mainly uses evaporation, magnetron sputtering and other surface deposition processes to metalize the surface of the substrate, first sputtering titanium under vacuum conditions and then sputtering copper particles, and then electroplating and thickening, using the image transfer method to make the circuit on the thin film metalized ceramic plate. Then a ceramic circuit board with high density double-sided wiring is formed by electroplating sealing technique.

DPC ceramic substrate has many characteristics, such as high thermal conductivity, high insulation, high line accuracy, high surface flatness, thermal expansion coefficient and chip matching, and quickly occupies an important position in high-power VCSEL component packaging.

VCSEL - The future is waiting

The rapid development and unique advantages of VCSEL have made it a key device in optoelectronic applications, with strong vitality. In recent years, VCsels with excellent performance have been continuously researched and developed, mainly involving its low threshold current, high output power, high electro-optical conversion efficiency, low operating voltage, high modulation bandwidth and high yield.

It is believed that driven by the demand of 3D sensing, 5G communication and other fields, as well as the R&D investment and experience accumulation of various manufacturers, the global use of ceramic circuit boards to package VCSEL chips will make great progress, and expand more and more application fields.

Follow us

customer service